DISCLAIMER Throughout this publication, reference is made to a number of pesticides (herbicides, fungicides and insecticides) which have been used either commercially or experimentally in miscanthus production. It should be emphasised that with any pesticide application the relevant legislation (Health and Safety at Work Act 1974; Poisonous Substances in Agriculture Regulations 1984; Food and Environment Protection Act 1985; Control of Pesticides Regulations 1986; Control of Pollution Act 1974; Plant Protection Products (Sustainable Use) Regulations 2012 etc.) and the Product Label Recommendations must be adhered to.

1.0 INTRODUCTION

1.1 MISCANTHUS

Miscanthus spp. are rhizomatous perennial grasses native to East Asia, displaying lignified stems resembling bamboo. Once the plants are established (typically requires 3-5 years) miscanthus has the potential for very high rates of growth, growing stems that are over 3m within a single growing season. While there are many miscanthus species, Miscanthus x giganteus is the main crop for biomass production. M. x giganteus is a sterile hybrid between Miscanthus sinensis and Miscanthus sacchariflorus. More hybrids have been developed in recent years and are now commercially available. Miscanthus is planted in spring and once planted can remain in situ for at least 15 years (15-25 years). The miscanthus leaves fall off in the winter, contributing to the development of soil humus and nutrient cycling. Miscanthus produces bamboo-like canes during late spring and summer which are harvested in late winter or early spring.

This growth pattern is repeated every year for the lifetime of the crop. Miscanthus differs from short rotation coppice willow in that it gives an annual harvest and thus an annual income to the farmer. Miscanthus spreads naturally by means of underground storage organs known as rhizomes. However, their spread is slow and there is little risk of uncontrolled invasion of hedges or fields. These rhizomes can be split, and the pieces re-planted to produce new plants. All propagation, maintenance and harvest operations can be done with conventional farm machinery. On mainland UK an average yield of 8.4 tonnes dry matter per hectare per year (DM/ha/yr) is to be expected from a mature crop (i.e. excluding the first 3 years). In Ireland, including trials in Northern Ireland, long-term average harvestable yields have exceeded 5 DM/ha/yr from a mature crop. These yields suggest miscanthus has the potential to make an important contribution to renewable energy generation. More recently, miscanthus has been used in biocomposites and building materials. With the yields observed, if grown on a larger scale in the UK, could also contribute significantly to the sustainable building sector.

1.2 GROWTH CYCLE

The growth pattern of the crop is simple. From the underground rhizomes new shoots are produced annually. These shoots develop into erect, robust stems, which reach 0.5 – 1 m in height by late August of the first year of planting, with a diameter of up to 10mm. The stems, which have an appearance like bamboo canes, are usually unbranched and contain spongy tissue, called pith. From the third season onwards, the crop can be expected to achieve a maximum height of 3-4 m.

From late July the lower leaves senescence as canopy closure prevents sufficient light penetration. Following the first air frost in autumn, senescence accelerates and nutrients move back to the rhizome. Leaves then fall and a deep leaf litter develops. Any remaining foliage dies, and the stems dry to relatively low moisture content (30 – 50% MC) during winter. By February, free standing, almost leafless canes remain, and it is these which are harvested mechanically. This growth cycle is repeated once spring-time temperatures increase again.

In year 1 miscanthus grows to approximately waist height producing 2 or 3 canes. In year 2 it grows to approximately head height with ~15 canes and in year 3 it grows to about 2.4m in height with about 50 canes. Miscanthus is in a yield building phase over the first 3 years. Miscanthus is a C4 plant, like maize. C4 crops utilise the C4 photosynthetic pathway, in contrast to the C3 pathway utilised by standard arable crops in Northern Europe (such as wheat, oilseed rape potatoes). Therefore, it shows a higher solar radiation conversion efficiency than C3 plants. Additionally, it’s more efficient in its use of nitrogen and water. C4 plants tend to originate from warm climates, thus, miscanthus prefers warmer temperatures. Growth potential of miscanthus is dependent on temperature, daylight hours, the water capacity within soil and the rainfall levels. Therefore, sunlight, day length and moisture are key factors for a successful crop.

2.0 PRE-PLANTING

2.1 SITE SELECTION

2.1.1 SUITABLE SOILS

Miscanthus has been reported growing and producing reasonable to high yields on a wide range of soils, from sandy to organic matter rich soils. However, waterlogged soils and stony soils should be avoided. Deep soils with high water retention capacity are preferred. Miscanthus is also tolerant of a wide pH range, but the optimum is between pH 5.5 and 7.5. Miscanthus is harvested in the autumn and later winter/early spring, therefore, it is essential that the soil does not get excessively wet during this period, as this may limit accessibility for harvesting machinery and cause damage to the soil structure. Growing miscanthus on very heavy clay soils in certain circumstances should therefore be avoided.

2.1.2 WATER AVAILABILITY

Annual rainfall and soil water retention will strongly influence the yield of miscanthus at any site. Miscanthus possesses good water use efficiency when considered based on the amount of water required per unit of biomass. Additionally, miscanthus roots can penetrate and extract water to a depth of around 2m. However, to maximise miscanthus’ potential yield, additional water may be needed when compared to the traditional crops it has replaced. What is more, research at Teagasc (Oak Park, Ireland) has shown that up to 50% of rainfall can be intercepted by the dense canopy, evaporating off the leaves and never reaching or penetrating the soil. Hence, limited soil water availability during the growing season will prevent the crop from fulfilling its potential yield that year. Yield loss due to soil water deficiency has been calculated at 90 kg DM/ha/yr for each millimetre of soil water deficit. Regardless, irrigation is not justified economically by the value of increased biomass obtained. In times of severe drought miscanthus foliage will first display leaf rolling, then dying back from the leaf tip. This will reduce yield in the year of drought but in all cases experienced in Ireland and the UK to date the crop will survive and re-grow the following year.

2.1.3 TEMPERATURE

The potential cropping zones for miscanthus are widespread. Miscanthus does not grow at temperatures below a threshold of 6⁰C. This is considerably lower than maize and therefore the potential growing season is longer. Late spring frosts which destroy early spring foliage reduce the duration of the growing season and can be a constraint to seasonal growth in miscanthus. However, commercially available hybrids of miscanthus have been shown to survive severe winter temperatures of -14ºC. As with most plants, temperature is a limiting factor for growth. Miscanthus, originating from warm climates in East Asia, displays optimum photosynthesis rates at around 35ºC and is suggested to be tolerant to extreme high temperatures, beyond the norms of current northern European climates. Nonetheless, Miscanthus hybrids exhibit greater net CO2 assimilation rates at cooler temperatures (10–18 °C) than other C4 crops and produce a greater leaf canopy before other C4 crops in temperate zones.

2.1.4 SITE ACCESS

Green harvesting (before senescence - the process where plants carefully deconstruct cellular structures and reassimilate nutrients into the roots) occurs in autumn and brown harvesting occurs after leaf senescence, in late winter or early spring. In either season, soils can have high water contents. Thus, hard access would be advisable to support the movement of harvesting machinery and harvest material to and from the site.

2.1.5 SUITABLE LAND AREA

It has been found that miscanthus planted in small fields (~1 ha) and fields with awkward shapes and terrains can still produce satisfactory gross margins. Additionally, miscanthus can also be grown in areas of poor soil quality. Miscanthus production in these unfavourable fields and conditions provides a lucrative application option with minimal time and labour requirements, as establishment only occurs once followed by continual annual harvesting over a period of at least 15 years. However, the economies of scale still apply, with fields of greater land area leading to lower production costs. Hence, it is more economical to plant larger land areas. If the option is there to plant fields of the same quality but differing in sizes, then the larger field would be the best option. However, if marginal (less favourable) land is available, and will suffice for the intended end use, then these areas can also be productive and potentially more economical if other larger areas can be utilised for more profitable land uses.

2.1.6 LOCATION IN THE LANDSCAPE

Since miscanthus can exist on site for at least 15 years and can reach up to 3.5m in height it will have long term, 3D impacts on its local landscape. This should be addressed if the site is close to a footpath or viewpoint. Impacts on wildlife, archaeology and public access must also be considered prior to planting. In addition, the impact of harvesting machinery on the soil should be considered. Soil diffuse pollution should be prevented by ensuring soil compaction is minimised and soils retain good structure. Furthermore, if the land has not been cultivated for the last 15 years or is classified as semi natural then an agricultural environmental impact assessment (EIA) must be carried out.

England - https://www.gov.uk/guidance/eia-agriculture-regulations-apply-to-make-changes-to-rural-land

Northern Ireland - https://www.daera-ni.gov.uk/articles/environmental-impact-assessment-eia-0

Scotland - https://www.gov.scot/policies/environmental-assessment/environmental-impact-assessment-eia/

Wales- https://www.gov.wales/assessing-environmental-impact-agriculture

2.2 SITE PREPARATION

Thorough site preparation is essential for good establishment, ease of subsequent crop management and high yields. As the crop has the potential to be in the ground 15-25 years, it is important that it is established correctly to avoid future problems.

2.2.1 PRE-PLANTING PEST CONTROL

In the first two years, miscanthus canopy coverage is not 100% and weeds can persist. Hence, weed control is key for the establishment of miscanthus, an uncontrolled weed infestation may become a severe infestation if left untreated. Weeds, in extreme cases, have caused up to 68% plant mortality.

For grasslands with heavy weed presence the first step before planting is to spray the site with an appropriate translocated (systemic) herbicide (e.g. glyphosate 360 g/l product at 4-5 l/ha) to control perennial weeds. This should be undertaken in early autumn when weeds are still actively growing before autumn ploughing, if local regulation permits. If leaving fields fallow or as dead sward is not permitted, then spraying will occur in late winter/early spring. If necessary, the translocated herbicide can be re-applied prior to spring cultivation. A translocated (systemic) herbicide (e.g. Glyphosate - 360 g/l product at 3 l/ha) should be applied in late winter/early spring (10 days should be left between herbicide application and ploughing).

Non-chemical methods include mechanical fallowing to reduce weed seed reserves. This can be followed by planting a winter annual cover crop in late summer/autumn prior to planting the rhizomes, similar to traditional farming practices. For cover cropping, in addition to removing top growth of any existing weeds, seedbed preparation should include chopping up or otherwise disrupting the rhizomes, rootstocks, and other belowground structures of perennial weeds. It’s vital to make sure that weed seeds are not germinating just below the surface when you plant the cover crop. Thus, the final shallow tillage to finish the seedbed should take place one the same day before planting. Legumes are particularly good cover crops where there is limited N and where lots of soluble N is available over winter cereal ryes are good as they rapidly take up and outcompete weeds for soluble N.

If leather jackets are an issue, insecticidal control is not permitted, thus cultural practices to reduce crane-fly populations in the late summer/autumnal period should be encouraged. E.g. cutting tussocky fields if necessary to try and reduce egg laying habitats. Additionally, encouraging bird populations using bird friendly hedges and crop borders in the headlands. What is more, larvae populations can be reduced through stale seed bed practices. Again, ploughing in late winter/early spring before planting can disrupt larvae and expose larvae to feeding bird populations. Water management is also important for leatherjacket management. Overly wet soils promote leatherjackets. If using a green manure/cover crop and leatherjackets pose an issue, spring alfalfa must be avoided.

2.2.2 SOIL TESTING & MANAGEMENT

Soil testing should be undertaken before planting. The pH and Soil Nitrogen Supply (SNS), phosphorous (P), potassium (K) and magnesium (Mg) indices should be screened for and can be adjusted during the site preparation stage if needed. There are multiple soil testing companies which can offer services with in-depth soil analysis and reporting. Even field level analyses can be provided to help carry out targeted nutrient application.

Based upon the results of the soil tests, nutrient or lime application, if necessary, can be carried out to adjust the levels to the optimal conditions for miscanthus. It should be noted, unnecessary fertiliser application may only encourage weed competition during establishment.

What is more, baseline soil analysis can be used for predictions of nutrient application based on yields and offtakes once the miscanthus system has been established (see section 4.4), whilst also identifying soil carbon stores.

List of soil testing facilities - https://ahdb.org.uk/knowledge-library/soil-and-forage-testing-companies

2.2.3 PLOUGHING

If necessary, and taking the chemical control method route, the site should be sprayed, before ploughing in the autumn prior to planting or late winter/early spring, depending on what local regulations permit. At least 10 days should be left between spraying and ploughing. Ploughing should be undertaken to a depth of 20-30 cm. Ideally this should be undertaken before the frost period is up, allowing the frosts to break down the soil even further. This may also help prevent ‘ley’ pests such as the larvae of two moths; the common rustic moth and the ghost moth attacking the newly established plants, as any larvae or eggs already in the soil from the previous crop will have insufficient food over the winter to survive.

Later in the spring from March to April the site should be rotavated or power harrowed immediately prior to planting. This will not only improve establishment by further physically removing competitive weeds, aiding good root development, good soil root contact and improved soil aeration but will also improve the effectiveness of any residual herbicides, applied after planting.

If following a nonchemical practice, then the cover crop can be plough and harrowed as with chemical practices into the tilth to terminate the cover crop and incorporate the plant material back into the soil nutrient cycle.

2.2.4 EXCLUDING VERTEBRATE HERBIVORES

Rabbit, hare, deer geese and pigeons can all cause damage to young miscanthus plants. Deer will feed on the leaves when still green, rabbits and hares will eat the new growth shoots, similarly to pigeons and geese. Damage caused by deer, rabbits and hares can be mitigated by fencing in new crops before sowing rhizomes. However, fencing is an extremely costly process and only needed during the establishment phase. Thus, alternatives such as Garlic Barrier can be used with weekly applications on the total crop (1-2 l/ha) when the crop has freshly emerged. If there are grass headlands, then applications of Garlic Barrier just to the headland works well but will need reapplying after heavy rain. If the infestation of rabbits is particularly high, then Grazers applied directly to the miscanthus plant at a rate of 250-500 ml/ha depending on severity.

2.3 VARIETY SELECTION

The miscanthus variety grown in the UK is M. x giganteus a sterile hybrid. This variety has been grown in the UK for over 25 years and has clearly demonstrated non-invasiveness, longevity, and excellent tolerance to UK weather conditions. Miscanthus is a perennial crop that is harvested annually. Most arable farmers will be more familiar with annual crops which are replaced each year.

The UK cereal seed industry presents a good example of this annual replacement. It has a high turnover of new varieties, chosen not only for commercial reasons, but for yield increase, disease resistance, ripening dates, straw length, quality and end markets. If the occasional new variety does not perform well it can easily be replaced in the next cropping year.

New varieties of miscanthus, being a perennial crop, present a different set of criteria. Yield will always be a key criterion, however, suitability to long term cropping, longevity, non-invasiveness, winter hardiness, harvesting and end uses must also be considered for new varieties. Probably the biggest consideration for future Miscanthus varieties is tolerance to future extreme weather events brought about by a changing climate.

We already know that water is the largest contributory yield factor of Miscanthus (C4). Miscanthus has twice the water efficiency of maize (C4) and four times the water efficiency of wheat (C3). Therefore, Miscanthus grown on high water table/high rainfall/good moisture retentive land areas will always yield higher than those on lower water tables regardless of variety. Miscanthus crop yields are also subject to soil type, the timing of annual rainfall and daylight hours, so a variety that may be suitable for the South of the UK, may not be suitable for the North. Thus, comparisons and testing of new varieties poses a challenge which requires collaborative trialling. New Energy Farms, Terravesta, and Miscanthus Nursery are all involved with the development and monitoring of new varieties.

Miscanthus is now being grown commercially in many parts of the world, not just the UK. Technically it is a ‘high biomass grass’ and like any grass it will be susceptible, in principle, to insect, fungal and other diseases. However, miscanthus appears to be remarkably robust and there are virtually no reports of significant crop damage in the key areas of expanding production: the USA ,Canada, EU countries and New Zealand.

Albeit its remarkable robustness, a technology utilised in the SRC willow industry is the growing of mixed varieties to reduce the threat of pest and disease. This will no doubt be a consideration for the future in miscanthus trials.

2.4 PLANTING MATERIAL

Miscanthus hybrids tend to be triploid and therefore sterile. Hence, rhizomes tend to be the main propagation material. Using vigorous and healthy planting material is vital. For phytosanitary reasons, miscanthus rhizomes should only be sourced from UK or EU member state suppliers. Additionally, no rhizome certification or quality standard protocols are in place. Thus, taking measures to ensure rhizome quality is critical to guarantee successful germination and establishment.

2.4.1 RHIZOMES

2.4.1.1 PROPAGATION MATERIAL

There are two methods of miscanthus propagation, rhizome division and micropropagation. Rhizome division is favoured because it is less expensive and generally produces more vigorous plants. To produce new planting material, 2 or 3 year old rhizomes in the ground are split using a rotary cultivator whilst dormant (late winter), and the rhizome pieces collected for re-planting. The mechanically cut rhizomes of 20-100 g/rhizome must either be planted within 4 hours of harvesting or be stored as quickly as possible (<4 hours). Rhizomes left on top of the soil after harvesting will begin drying after 3 hours and viability will decrease. Thus, it’s crucial that the harvested rhizomes are prevented from drying out from the time they are lifted from the soil until they are planted again. Cold storing rhizomes and wrapping them in polythene can prevent water loss and maintain dormancy. Rhizomes stored at <4ºC for 4 months, showed less than a 20% reduction in viability. Additionally, rhizomes can be stored heaped in the field with a covering of moist soil for a short period of time.

2.4.1.2 RHIZOME SIZE

Rhizomes will vary from the size of your thumb to the size of your fist. Chopping rhizomes in the field is not a precision job. A lot of buyers don’t like the little rhizomes as they feel there is less of a chance of establishing them. However, germination tests carried out by Teagasc, Ireland, have shown germination rates of over 90% with viable rhizomes (at least 2-3 buds). Alternative research has suggested that weight and length are also viable methods for increasing germination success. A weight of at least 60-75 g/rhizome or have a length of >10cm have been suggested. However, AFBI (Hillsborough, Northern Ireland) have found that, providing rhizomes have viable buds, breaking the rhizome into smaller pieces (25-30 g/rhizome) rather than larger pieces (60-75 g/rhizome) generates more shoots per kilogram of rhizome planted. It should be noted, this was carried out in a cool, wet environment where drying would not have been much of an issue. Larger rhizomes will have a greater tolerance to desiccation.

2.4.2 PLANTING MACHINERY

2.4.2.1 SPECIALIST PLANTERS

Hand and Automatic two and four row planters have been developed for use in the UK. These are based on ex potato planters but have been modified to provide accurate flow of rhizomes into coulters to achieve accuracy of depth and within-row placement. Both W.H.Loxton & Terravesta, have developed a range of machinery to tackle the challenges of energy crops. These machines can handle all known rhizome types. The planters can cover more than 4 -20 ha/day. These machines can variably rate plant from 11,800 to 59,000 rhizomes/ha. The planters have 0.75m to 1.0m row spacing.

2.4.2.2 MODULAR POTATO PLANTER

For rhizomes destined for use in the potato planter, grading is required to remove rhizomes which will not pass down the planting tube or have less than 2-3 buds. Once graded, the operator of the potato planter places rhizomes into a cup or drops them down a planting tube. The distance between plants is governed by the speed of a land wheel. As the rhizomes enter a furrow opened by a share, the soil is ridged over the rhizomes. The potato planter should be followed by a heavy roller, to aid soil consolidation. The work rate achieved is low (0.3 ha/hr.) but might still be suitable for planting small areas. This technique ensures accurate placement and good depth control, both of which are important for good establishment success.

3.0 PLANTING

The optimal planting time for rhizomes is from March to April, when average soil temperatures are >8ºC, but planting can continue into May and even early June and still be successful. Early planting takes advantage of spring-time soil moisture and allows an extended first season of growth. This is important because it enables larger rhizome systems to develop. Crops with larger rhizomes are more robust in future years, allowing the crop to better tolerate drought and frost.

3.1. PLANTING DENSITY

A planting rate of 15,000-20,000 rhizomes/ha is recommended, depending on soil type and condition, to aim to give an emergence of 10,000-15,000 plants/ha. This rate allows for some establishment losses while still providing the plant density required to achieve optimal yields from year three onwards and effective weed suppression through competition in establishment. The greater the planting density, the greater the weed suppression. So, if planting in weed infested soils consider higher planting densities (>20,000 rhizomes/ha). What is more, if planting in cooler, moister climates, then rhizome splitting and planting at a higher planting density should be considered.

3.1.1 CALCULATING PLANTING DENSITY

The ‘optimal’ planting rate has been suggested to be ~16,600 rhizomes/hectare to get an establishment of more than 10,000 plants/ha. This can help avoid the cost of gapping-up areas where establishment did not occur. 16,600 rhizomes/ha allows for some rhizome losses during the establishment phase.

Spacing standardly used are 0.75-1.0 m wide planting at 0.5-0.75 m spacings. For example, to achieve 16,600 rhizomes/ha, a rhizome should be planted at 0.8 m with 0.75 m spacings. This gives 133 rhizomes/100 m. 1 ha is 100m by 100m, hence:

16,600 rhizomes/ha=(100 × 100 ×133)/80

3.2 PLANTING DEPTH

Rhizomes should be planted to a depth of around 7.5-10cm.

3.3 BIODEGRADABLE PLASTIC MULCH

Miscanthus, like forage maize, is a plant originating from a warm climate and which responds to higher temperatures. Trials at AFBI (Northern Ireland) have shown that when the plastic mulch system used for forage maize is applied to miscanthus (covering the rhizomes straight after panting), average soil temperatures can be raised by 2.5ºC. Thus, accelerated crop development occurs in the spring growth phase and an increase in the number of shoots and biomass is observed in the first year. Although the plastic mulch breaks down during the first season, the increased shoot numbers and higher biomass per year continue into the 2nd and 3rd seasons, but with diminishing effect as internal competition within the crop itself becomes the main limiting factor. Additionally, mulching can suppress the growth of competing weeds, reducing the need for costly pesticides. Despite additional costs biodegradable mulching incurs, it represents an economic benefit to the crop.

4.0 POST PLANTING ESTABLISHMENT

4.1 NUTRITION & FERTILISATION

Miscanthus is very efficient in the way it uses nutrients. There are several reasons for this high level of efficiency.

- Miscanthus is deep rooted and can extract nutrients from a large area of soil.

- Miscanthus has a high nutrient efficiency compared to arable crops (wheat, barley) and native grasses (ryegrass).

- Less nutrients are needed for each kilogram or unit mass of biomass produced by the crop.

- Excess nutrients are exported from the above ground parts to the rhizome during the autumn as the leaves senesce (return nutrients to plant, die and fall off). The nutrients are stored in the rhizome during the winter and are used to support early growth of shoots during the following spring.

- Leaves fall off the Miscanthus stems as winter progresses and accumulate as a litter layer on the surface of the soil. The litter layer decomposes over time and the nutrients recycle back into the soil where they can be once again absorbed by the root system. Additional nutrition is available to the crop through atmospheric deposition and soil mineralisation.

Nutrient off-takes are confined to the amount of nutrients in the stems at harvest as nutrients in the leaves are returned to soil. Final harvest yields and consequent nutrient off take will depend on crop productivity. Crop productivity will depend largely on rainfall and temperature in the case of Miscanthus. Research from experiments conducted throughout Europe have shown that nutrient off-takes from productive crops (10-15 tonnes DM/ha/year) may fall in the following ranges.

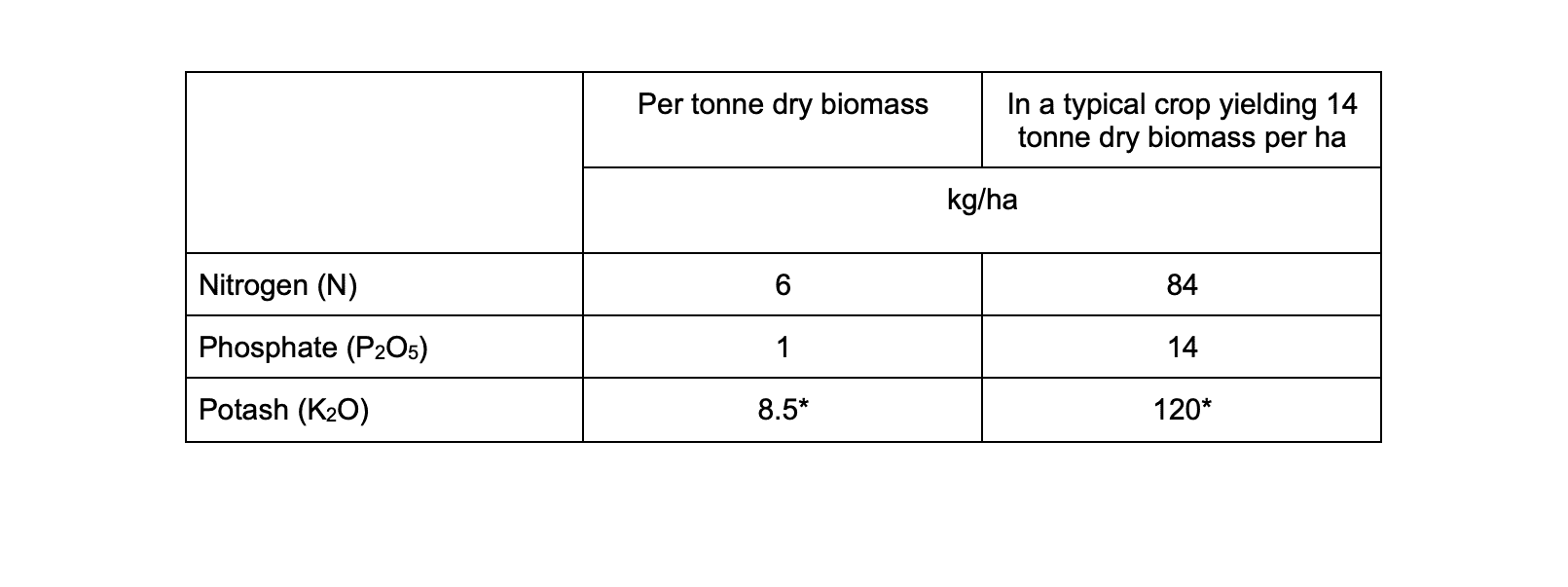

Table 1 - typical offtake of nutrients in harvested biomass (excluding the first two years after planting when yields are much lower than in later years).

*Potash offtake in Miscanthus is very variable as it is affected by weather and time of harvesting. These values refer to crops harvested in January; it is now common for crops to be harvested later (e.g. April–May) and the offtake of potash then is generally less because rainfall leaches out potash from the standing crop and returns it to the soil.

Uptake of potassium and nitrogen is broadly similar and considerably greater than phosphorus uptake.

Many nitrogen fertiliser trials have been conducted on Miscanthus. In some cases, a biomass yield response to 50–100 kg N/ha has been observed. Most research shows no response to higher N rates. Some research has shown no response for many years (up to 15 years). The Soil Nitrogen Supply (SNS) Index of the field should be determined along with the indices for P and K. Based on a field that was previously used for arable farming (SNS index = 2), annual fertiliser applications in the range of 60–80 kg N/ha (or organic applications estimated to supply this quantity of nitrogen) are likely to provide sufficient nitrogen for maximum production. In soils starting at a higher SNS Index, nitrogen applications are probably not required for some years.

Many sources suggest that nutrient offtake at harvest can be balanced by the mineralisation of soil organic matter as well as by atmospheric deposition. However, crop nutrient requirements will ultimately depend on soil type, cropping history and nutrient offtake. Growers are advised to make use of regular soil tests to determine that sufficient levels of nutrients are available in the soil.

It is generally not recommended that any fertiliser be applied in the first two years as offtakes are low and there should be sufficient nutrients in the soil. Typically, fertiliser application during these years will only promote weed growth which will compete with miscanthus plants and incur additional expenditure on herbicides. However, if deemed necessary through soil sampling and analysis, P and K only fertilisers can be applied in establishment years. Fertiliser requirements for subsequent years are summarised in the tables below. Recommendations:

- Check soil nutrient indices before planting, then every 3-5 years.

- SNS index, if extremely low (< 2) then nutrient application can occur, however, industry standard is generally not to add N.

- Maintain soil at P Index 1.

- Maintain soil at K Index 1–2.

The following preliminary nutrient advice has been developed for miscanthus. This advice may change as additional information on the crop becomes available. The philosophy is based on replacing nutrient removal by the crop.

Conclusion: The foregoing presents some preliminary nutrient advice for Miscanthus crops. However, relatively little is known about miscanthus and the way the crop uses nutrients. Further research is needed to learn more about the nutrient requirements of Miscanthus.

4.1.1 MANURES AND DIGESTATES

Livestock manures are also an option in terms of meeting the nutrient requirements of miscanthus. Livestock manures are governed by nutrient legislation (SI 610 of 2010, Nitrates Directive) in ROI and RB 209 in the UK. For example, cattle slurry can be used as an effective nutrient source for miscanthus and can be applied annually to satisfy crop nutrient requirements. Cattle slurry contains a total of 5Kg N/m3, 0.8 kg P/m3 and 4.3 kg K/m3. Miscanthus grown on a soil P index of 1 requires approximately 28.75m3/ha cattle slurry (23/0.8) to satisfy its annual P requirement. The slurry would provide 57.5 kg N/ha and 123.6 kg/K/ha per application.

4.2 WEED CONTROL

Weeds, if not controlled, will compete with the crop for light, water and nutrients, thus reducing yields. The level of weed interference will depend on the stage of maturity of the crop (i.e. its ability to out-compete weeds), the degree of weed infestation at the site and the diversity of the weed species (affected by location, season, climate and previous land use). Weed control is essential in the establishment phase of the crop because the slow initial growth of miscanthus reduces its ability to compete. The planting process causes soil disturbance which promotes seed germination. Furthermore, the low planting densities which are used results in large unoccupied spaces where weed growth can occur.

As the Miscanthus crop becomes more established, a range of selective herbicides can be used for weed control. Most active ingredients which are appropriate for cereals could also be suitable for miscanthus (with the possible exception of some graminicides) and some C4 specific herbicides can also be used. Off-label approval has been given for the use of many cereal herbicides in miscanthus.

Once the full canopy develops, the germination of new weed seedlings is dramatically reduced, and only shade tolerant varieties such as black-bindweed and chickweed or particularly mature individuals will survive. Autumn germinating species such as Annual meadow grass may present problems after crop senescence has occurred in the establishment year.

Weed control in the establishment phase of the crop is essential because infestations can severely check the development of the crop. It’s vital that proposed sites should be cleared of perennial weeds before any planting takes place (Pre-planting weed control has already been discussed in section 2.2.2).

Before the use of any chemical product, growers should refer to the Off-Label Extension of Authorisation for Minor Uses (EAMU) databases provided by local governing bodies and always adhere to the directions for use on the instruction sheet – it is an offence to use products in a manner that has not been approved.

The Department of Agriculture, Food & the Marine - Pesticides Control Service has given off-label approval for some used on miscanthus. Visit: http://www.pcs.agriculture.gov.ie/. To see GB and NI off-label approvals visit https://secure.pesticides.gov.uk/offlabels/search.asp.

4.2.1 POST-PLANTING WEED CONTROL

Within 14 days of planting, spray a pre-emergence herbicide onto a moist soil. A high-water volume of 500 l/ha is essential to give a good coverage of chemicals on the soil. For example, apply the 500 l of water together with 3.3 l of Pendimethalin (455 g/l) together with 1.5 litres of isoxaben (125 g/l). Between the period of sowing and germination, if weed presence is observed, blind harrowing to a depth where the rhizomes will not be disturbed can be utilised to destroy weeds. What is more, if weeds emerge after sufficient growth of the rhizomes, then inter-row cultivation can be used to mechanically destroy germinating weeds.

4.2.2 POST-EMERGENCE WEED CONTROL

Once miscanthus shoots have emerged, selective herbicides may be used for the control of vigorous annual dicotyledonous weeds. A weed wiper may be used to apply post-emergence roundup to the taller, more persistent weeds such as thistles. Spring cereal broadleaf weed herbicides can generally be used on miscanthus.

Again, inter-row cultivators can be used for the removal of weeds between rows. Weeds are most susceptible to damage during their 2-4 leaf stage. So, controlling weeds must occur when weeds are young.

Hence, from May to August walk the fields on a weekly basis. Check for herbivore and leatherjacket damage. Monitor weed populations and take remedial action in worst case scenarios.

4.2.3 END OF 1st GROWTH SEASON WEED CONTROL

Miscanthus crops while dormant have only very small amounts of green material present in the Miscanthus leaf or stem. Growth will only re-commence in late March or early April. Glyphosate being a systemic herbicide will kill or check the plant if there is green material in the plant. Some first-year crops do not lose all their green leaf so to spray glyphosate in such circumstances the crop should be failed or topped within 24 hours of application. This will prevent any glyphosate taken into the plant through green matter translocating to the rhizome.

Glyphosate (4 l/ha.) should be sprayed across the entire crop normally from mid- February onwards where grass weeds are present. If there are little or no grasses present, there should be no requirement for glyphosate. Spraying of glyphosate should normally be completed by Mid-March. Note this is a time critical operation and only if carried out correctly will eliminate the grass weeds which otherwise cannot be treated as miscanthus itself is a grass species.

There also have been some reports of crops grown on high organic (peaty) soils where glyphosate persistence has been reported. IBERS researchers in Wales adopted a management system from 2009 of topping anytime from January 20th and spraying glyphosate (360 g/l product at 4 l/ha) as soon as possible after topping and applying a soil acting herbicide 3 – 4 weeks later. This has proved very effective.

4.2.4 WEED CONTROL IN OLDER PLANTS

If weeds persist into the later stages of the growing season, herbicides that are safe to use on miscanthus up to 1 m high can be used on older plants. Additionally, if weeds issues are localised at this stage then take targeted action using a knapsack and miscanthus safe herbicides. Generally, from year two onwards the crop will suppress weed growth and chemical control should no longer be required.

4.2.5 2nd/3rd GROWING SEASON

Once the crop has established (i.e. from the summer of the second or third year, depending on site and climate), weed interference is mostly suppressed, initially by the leaf litter layer on the soil surface and subsequently by the closure of the crop canopy. This reduces the light penetrating into the understory. Weeds that do survive offer little competition to the crop. Since there are no label recommendations, all products are used at the user’s own risk. Weed control is likely to be relatively intensive after planting and during the establishment phase. However, once the crop has become established, the demand for weed control is low. However, if weed problems occur after the establishment phase, then locating these issues and locally treating them is an option. It should also be noted, development of new weed fauna in long term plantations must be monitored to identify any ‘new’ weed species which will pose a threat to the crop.

4.3 GAPPING-UP

Patch-planting or infilling should be carried out during March/April where significant gaps appear in the crop – typically those gaps that amount to the size of a small car in area. For those patch-planted rhizomes to have a chance to survive, grass growth will have to be suppressed or killed in those areas particularly.

4.4 DISEASE & PESTS

Miscanthus species are susceptible to pests and diseases in the areas to which they are native (Asia) but, yet none have been reported in the UK or Ireland. Stem basal diseases may infect stems in the autumn or winter, reducing stem strength. There are no reported insect pests in Europe that have significantly affected the production of miscanthus. However, two ‘ley pests’, the common rustic moth and ghost moth larvae feed on miscanthus and may cause problems in the future. Rabbits, hares, deer, pigeons, and geese can also pose a problem in establishing a new miscanthus crop as they like to feed on the fresh emerging leaf as the crop grows initially. Fencing may be required if deer and rabbits pose a serious threat to establishment.

4.4.1 COMMON RUSTIC MOTH

The larvae feed from autumn until May on miscanthus grass roots and other grasses including cock’s-foot. These larvae overwinter once before becoming adults which can be found resting in a wide variety of habitats. Concealed in ground vegetation by day, it becomes active after dark. They are particularly attracted to flowers of the common ragwort and marsh grasses.

4.4.2 GHOST MOTH LARVAE

Ghost moth larvae are subterranean and rarely seen, feeding on roots of the miscanthus and other grasses. It takes two years to develop into a moth, thereby over-wintering twice. Ghost moth adults are often found in grassy embankments, fields, and hillsides. The males can often be in flight at dusk on warm evenings swaying up and down amongst tall grassy vegetation.

4.4.3 WIREWORMS

Wireworms are the larvae of click beetles. They are yellow larvae with distinct legs at the front and two dark spots at the tail and bite into stems at the soil surface causing a hole with tattered edges. By the time this is evident, wireworms have usually moved along rows to attack further shoots.

Adult click beetles cause no economic damage. They live for about a year and lay eggs in grass fields. Larvae then feed for five years before pupating in the spring. Numbers increase over the years; highest populations occur in old permanent pastures. Wireworms feed in ploughed-down turf for about six months before moving to the surface to damage the next two crops.

Wireworm damage has been suspected in some cases of lower yielding miscanthus. They have become a more serious pest since the withdrawal of organochlorine insecticides and the increase of winter cropping of cereals. They now affect all winter cereal or winter cereal/ley rotations. Heavy infestations can cause yield loss of up to 0.6 t/ha in cereals. Peas, linseed, and flax are more tolerant to damage than other crops.

Crops at highest risk are those sown within two years of ploughing out permanent pasture. However, any rotation with predominant winter cropping, particularly with grass weeds, is at risk. Populations can be very patchy, so estimating numbers is difficult. Examining soil cores in the field for larger wireworms or in the laboratory for smaller ones is costly and rarely justified. However, if wireworms/click beetles are noticed then control measures should be taken.

Interestingly the main natural enemies are fungi and parasitic wasps. Thus, encouraging biodiversity on the farm is imperative.

4.4.3.1 CULTURAL CONTROLS

- Consolidate seedbeds to restrict movement.

- Control grass weeds.

- Consider including a spring crop in the rotation.

4.4.4 FUNGAL PATHOGENS

Although not currently posing a serious risk to the miscanthus yields system in the UK and Ireland, fungal pathogens have been found on miscanthus plants. Though none have shown a significant impact on yield it’s imperative to monitor potential new emerging diseases. In research plots in Kentucky (USA) leaf blight, caused by Pithomyces chartarum, was observed on every establishing M. x giganteus plant.

Additionally, fungal pathogens such as: Fusarium spp., miscanthus blight (Leptosphaeria spp.), Helminthosporium spp. and Drechslera spp. have all been isolated from Miscanthus spp. including M. x giganteus.

5.0 HARVESTING

Miscanthus for brown use (i.e. combustion, animal bedding, and construction etc) is harvested annually during late winter/early spring, typically with conventional farm machinery. Green harvested miscanthus (used for anaerobic digestion, biofuels, and fodder/ensiling etc) can be harvested annually in late summer/autumn.

5.1 TIMING

After growing vigorously during the summer, Miscanthus stops growing during autumn. The leaves drop off the crop and the stems dry as the winter proceeds reaching a moisture content 20-30% the following spring. Harvested biomass with lower moisture content is easier to store and the calorific value of biomass increases with decreasing moisture content. Early harvesting of Miscanthus (January, February) can produce a product with high moisture and leaf content which will be unsuitable for many applications. In contrast, delayed harvesting (late April) can damage the new growth of the emerging crop. Research has also shown that harvest traffic can cause permanent damage to emerging shoots. Consequently, the optimum time of harvest is generally in March or early April.

5.2 MACHINERY

Miscanthus can be harvested with a modified forage harvester or mower and baling. Alternatively, the crop can be cut and chipped using a forager equipped with a Kemper and Orbis headers.

5.2.1 MOWING AND BAILING

The crop can be cut with a conditioner mower. Trailed mowers tend to work better than tractor mounted models. Conditioning breaks up the rigid stems, allowing accelerated moisture loss, and produces a light, rectangular windrow. This not only makes baling easier, but also helps in the drying of the material, by increasing the surface area and increasing air circulation in the windrow. Moisture content can reduce significantly if the crop is cut and left to dry in a windrow for several days if weather conditions permit. Optimum moisture content for storage is <16%.

The use of drum or disc mowers is not recommended as baler pick-up mechanisms will have difficulty with this material. An alternative to conditioner-mowers is mowing the crop with a forager equipped with a Kemper header and a drum which conditions the crop without chipping it. This method produces a windrow for subsequent baling, its advantages are a higher work rate and an enhanced capacity to deal with dense crops compared to conditioner mowers.

In all cases it should be noted that Miscanthus is a much harder material compared to grass and maize and higher rates of wear and tear can be expected. There are a number of different types of balers, each producing different bales (e.g. rectangular, round and compact rolls), suitable for different scales of energy combustion. Large rectangular and round balers can produce bales with a dry matter density of between up to 190 kg/m3 and weighing between 250 and 600kg. These balers generally have a capacity of 1 ha/hr. Once harvested, bales should be stored inside a shed or outside under cover. Covered storage will ensure that bales will continue to dry whereas bales stored without cover will deteriorate particularly if conditions are poor.

5.2.2 CHIPPING

Miscanthus can be cut and chipped in one operation using a forager equipped with a Kemper header. This method of harvesting involves one operation whereas two operations are involved when the crop is mowed and baled. Cutting and chipping produces a product in chip form which is suited for combustion in boilers and power stations. It is important to set the harvester to produce a chip size of 30-40mm; this can be achieved by adjusting the speed of the feed rollers and/or by reducing the number of knives on the drum. Smaller chip sizes have a greater tendency to heat during storage while larger chip sizes are likely to be unsuitable for the intake systems of boilers and power stations. If chipped material is >16% moisture content, then material should be further dried in a grain drying floor with pedestals in place to allow efficient air dispersal. At AFBI (Northern Ireland), material harvested at 24-28% moisture content was spread to a depth of 1-2 m on a drying floor and dried intermittently with unheated air, bringing it down to about 12% MC over a 2 week period.

5.2.3 QUALITY

To ensure the best quality of product, it is important that miscanthus is harvested at the correct moisture (<16%) and stored in a suitable manner to keep it dry. If material is harvested at >16% moisture content, then the material should be stored in a dry shed with an air flow to allow further drying to a stable moisture content. The leaf litter layer which gathers on the ground under the crop over the winter should not be harvested. This leaf material that sits on the ground is generally excessively wet as it is in direct contact with the soil. The leaf material will be decaying, mouldy, wet and will have a high probability of containing soil or small stones. Inclusion of this leaf material could lead to an increase in both moisture content and ash content and could contribute to higher chlorine levels which are undesirable from a combustion viewpoint within the harvested material. Additionally, nutrients within this leaf layer provide nutrition for succeeding crops. Consequently, mowing height and the height of the baler pick-up should be set to avoid picking up this material. Additionally, it is important that mown windrows are not raked together as this will gather any decaying leaf material that will have fallen from the plants over the year and through the winter whilst drying.

6.0 POST HARVEST

6.1 YIELD

Yields will vary according to age of the crop and environmental factors specific to any one site. The crop will take 3-4 years to reach a mature yield (up to 5 years on marginal sites). After this initial yield-building phase, the crop will continue for many years (at least 15 years).

6.1.1 YIELD AS PLANTS MATURE

The yield from the first season’s growth, at 1-2 tonnes DM/ha, is not worth harvesting. The stems do not need to be cut and so the stems may be left in the field until the following season.

However, if spring-time applications of translocated herbicides are planned then the miscanthus stems should be topped or flailed to avoid any risk of herbicide uptake into the rhizomes. From the second year onwards, the crop is harvested annually. The second-year harvestable yields may range from 4-10 tonnes DM/ha, and those in the third year may achieve between 12-15 tonnes DM/ha (estimated UK average). Harvestable yields reach a plateau after 3-4 years.

The reasons for the variation in the yield building phase duration and yield in the plateau phase depends on planting density, soil type and climate. At sites where water supply or exposure limits yield, there may be a longer ‘yield-building’ phase.

6.2 DRYING & STORAGE

6.2.1 CHIPPED MATERIAL

For chipped material, grain drying floors with pedestals installed, for even air distribution, are ideal for drying chipped miscanthus. Harvested material at a relatively wet MC (~25%) can be dried intermittently using unheated air within 2 weeks. If heated, using heat from your own material, this drying period can be shortened further.

6.2.2 BALED MATERIAL

Baled miscanthus can be stored in dry shed for long periods of time. Outdoor storage during the drier seasons is possible, however, if moisture levels begin to increase in the bales, quality can reduce drastically and rapidly.

The storage of Miscanthus bales should follow the same rules as the handling and stacking of any bales produced in agriculture. Bales should be stacked safely. Thus, stacks should be sited:

- Away from public roads and footpaths to reduce the risk of fire from discarded cigarette ends,

- Away from overhead power lines,

- Well away from residential properties and where several stacks are sited together, they should be built in a line across the prevailing wind and not less than 24 m apart. All stacks must not be higher than 1.5 times the shortest baseline measurement. Bales should be stacked on the unstrung sides and overlapping bale layers must be included at regular intervals, as well as binding in the vertical columns.

Whilst the stacking and loading of lorries is in progress, we would always suggest that any spectators and people involved should always remain either in their machines or at a safe distance.

6.2.2.1 BALE STORAGE

The best way to retain the quality of your Miscanthus product is to treat it like any other biomass material i.e. wheat, barley and oilseed rape straw. To have the driest material possible (which means higher energy value per tonne and less moisture penalties or possible rejection) it is best retained by being kept undercover immediately after harvest. Storage of bales outside can be acceptable practice if it’s managed correctly.

Outside stacks need to be built as high as is possible and then pushed together tightly as the machine and bale quality will allow. A correctly built stack should be safe and result in a minimum amount of product being exposed to the weather. It is very important that outside stacks are sheeted to prevent the top and possibly the second layer being spoilt, leading to material degradation. The consequences of bad storage are soddened or starting to rot bales because of being exposed to periods of wet weather. Such bales will inevitably not be suitable for their destined market. This must be considered by you when loading your material for collection.

In the examples above, each layer is stacked in packs of four, three or two; pack size will depend on your machine and operator confidence. The pack size of the top layer will be driven by the reach of your machine and attachment type. The width of the stack should be driven by site, yield and available sheet sizes. Ideally try and build stacks as high and as square as possible to ensure minimum losses. Leaving your baled material in small stacks in the field where harvested will lead to a potentially higher number of losses.

It is important that packs are interlinked as demonstrated above and pushed tightly together to ensure maximum stability. It may be necessary to nudge the stack from behind in the early stages of construction to prevent any bales falling from the rear of the stack.

6.2.2.2 STACK SITE SELECTION

Where is the best place for me to site my stack of bales?

- Security to satisfy insurance requirements

- Accessibility for lorries

- Distance from power lines

- Free draining ground or ideally a concrete or hardcore pad

- Good level site

- Free from holes, ditches, and other obstacles.

6.2.2.3 BALE DENSITY

Growers should ensure that the bales produced by your chosen contractor are baled to the correct density and shape to meet the conditions of a contracted sale. When baling is in progress it is important to physically check your bales at the start of the operation and monitor them at intervals throughout the day. Good, tight bales should feel hard when kicked and it should prove difficult to get your hands under the strings and lift the string to any distance. It should not be possible to pull the strings off a bale by hand.

Some of the problems of not having your product baled correctly:

- More broken bales when clearing fields, loading trailers and trucks etc.

- Excessive bale damage from handling equipment

- Un-storable in outside stacks, due to being on open bale

- Hard to achieve a tidy stack and build to a sufficient height

- Excessive use of indoor storage space

- Impossible to achieve maximum weight onto the Lorries resulting in increased haulage costs per tonne of material

- Possible rejection at process site.

- Increased baling cost to you the producer (because of more bales)

6.2.2.4 BALE SIZE

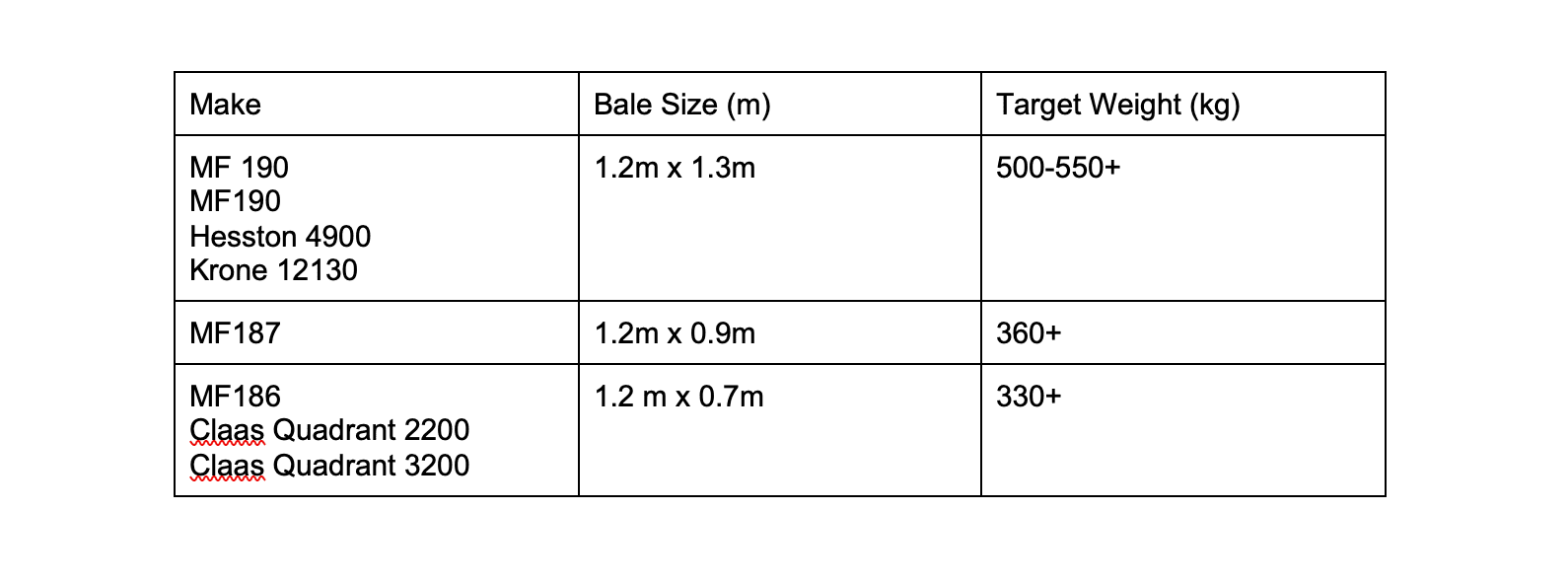

Please use the table below for the definition of bale sizes in relation to common baler models. All the below models produce 6 string bales. 4 string bales are generally not wanted as they do not lend well to haulage and handling systems. (e.g. Mini Hesston, MF182, Claas 2100). Bales should be produced 2.5 m (8ft) in length so as to ensure maximum weight per bale and value for money from the service supplied to you.

Table 2 - Common bale types, based on 15% moisture content.

6.2.2.5 BALE HANDLING

Having the correct handling attachment on your telescopic handler or loader will ensure ease of operation and enable efficient loading for the haulage company. Haulage companies will generally prefer the bales to be loaded lengthways along the vehicle bed. For this to be achieved when loading the vehicle, at least a two-pronged spike should be used, which can handle at least a couple of bales at a time. The more favourable alternative to this is possible, would be a multi bale grab. This type of loading grab is generally safer and considerably quicker to use. Lorries ideally need to be loaded within 45 minutes.

6.3 SITE RESTORATION

Miscanthus can easily be removed from an existing site by the application of a post-emergence non-selective herbicide such as glyphosate. This is followed by rotovating the crop to eliminate the miscanthus rhizome.

Allow the miscanthus crop to green-up after harvest and before the miscanthus is 1 m high (Mid - late May) spray with glyphosate (360g/l product at 5 l/ha). Plough and cultivate once the crop has died off. Grass will out-compete any surviving rhizomes.

This could be followed with discing to break up the rhizomes. If the miscanthus was a failure, there may not be any big rhizome stools to break up. Deep ploughing would bury rhizomes and they would struggle to re-emerge if they had any life left in them. Shallow ploughing may not bury any surviving rhizomes and they might re-emerge. If rhizomes were left exposed on the top of the soil for a while they would dehydrate and die, before being buried. So, there may be an option of not ploughing. When the new grass ley is mowed on a couple of occasions the energy stored in any surviving rhizomes will deplete.

Additionally, continual mowing to as short as possible throughout the growing season, will eventually kill miscanthus. This will most likely take 2 seasons. At least 2 mowings a year should be carried out, ideally monthly. However, miscanthus are good for soil restoration and continual mowing will cause soil compaction. An alternative option to mechanical mowing is intensive grazing. This is a method used in Japan to remove miscanthus: cattle, goats, sheep, and horses will preferably graze on miscanthus. Continual heavy grazing throughout the growing season will eventually kill the plant.

6.4 TRANSPORTATION

6.4.1 BALE TRANSPORTATION

Transportation of bales will be subject to restrictions on load dimensions and weight. Weights should not exceed a reasonable weight, having regard to the engine capacity, brakes, tyres, and general construction of the vehicle.

6.4.1.1 DIMENSIONAL LIMITS

Dimensional limits that apply to agricultural vehicles in the UK as of January 1, 2016:

Length = 12 m (or 18.75 m when combined – i.e. tractor and trailer or other interchangeable towed equipment).

Height = 4.65 m. Trailers used to transport loads of baled agricultural produce such as hay or straw etc. are exempt from this height limitation.

Widths =

- Agricultural tractors and trailers – 2.55 m;

- Large tractors – tractors with a laden weight exceeding 7.52 tonnes – 2.75 m;

- Tractors with flotation tyres or dual wheel systems – 3.5 m; and

- Fully mounted equipment and interchangeable towed equipment – 3.0 m.

The limit will allow ~31 large Heston square bales. If you are operating a stepped frame floor you will lose 2 bales on the floor, and you can only achieve 9 bales on the floor as opposed to 11 bales on a flat trailer and 11 bales on rows 2 and 3. Most trailers will only take 2 rows of large square bales height, but the step frame will go 32 bales in height allowing 31 bales in total.

The 8x4x4 bales tend to be around 500 kg in weight. Freshly baled miscanthus bales will be heavier than shed stored bales. The total tonnage is therefore 15.5 tonnes per load in large bale form.

6.4.2 CHIP TRANSPORTATION

When transporting miscanthus in bulk chipped form it can be transported on a walking floor trailer in 96m3 loads. Most operators report minimum loads of 11.5 tonnes per load at 20% MC indicating a bulk density of about 120 kg/m3. Were the miscanthus to be harvested at 50% MC there would be 20 tonnes on the load giving a bulk density of 200-210 kg/m3. It should be again noted, weights should not exceed a reasonable weight, having regard to the engine capacity, brakes, tyres, and general construction of the vehicle.

7.0 ADVANTAGES & DISADVANTAGES

8.0 LEGISLATION

There is currently little legislation relating to planting Miscanthus. This may change as Basic Farm Payment is phased out and Environmental land management systems (ELMS) and sustainable Farm incentive (SFI) are introduced.

When considering planting Miscanthus into long term permanent pasture (13 years plus) an environmental impact assessment (EIA) should be carried out. For full guidance please see:

https://www.gov.uk/guidance/eia-agriculture-regulations-apply-to-make-changes-to-rural-land

Soil samples should always be taken prior to planting Miscanthus, which should include P, K, Mg, and pH. It is also worthwhile sampling and asking for carbon report status on the soil, (this service is offered by most soil testing laboratories).

Miscanthus can virtually be planted anywhere the grower wants to plant the crop. However, consideration must be given to:

- Not blocking your neighbour’s view. A minimum of 10 m between the crop and the properties boundary is recommended.

- Not restricting visibility for road splays

- Leaving at least 3 m alongside a footpath or 3 m either side of a footpath running through a field

- Leaving access for Hedge cutting and or fencing for in field maintenance

- Turning spaces for Machinery

- Not planting directly under tree canopies, as this restricts both light and water getting to the crop

9.0 FLOOD MANAGEMENT REGIME

Some Miscanthus crops have experienced flooding over the years, particularly those grown close to rivers and on flood plains.

9.1 WINTER FLOODING

when miscanthus is going into dormancy or already dormant. flooding does not appear to be an issue. Crops of Miscanthus have been known to spend 2 or 3 months under water, and once the water has cleared, harvest albeit slightly delayed can take place. The very nature of the miscanthus rhizome root mass can support harvesting machinery in early spring despite the winter flooding, and invariably flooded crops always yield well due to the availability of water for longer periods of time.

9.2 SPRING/SUMMER FLOODING

Spring and summer flooding that may last for more than a few days is a problem to most annually sown crops. Permanent crops like miscanthus do appear more resilient. Miscanthus has been known to be underwater for up to 3 weeks during periods of heavy summer rain, resulting in only a slight yield reduction in the harvest following summer flooding, but has no adverse effects on any subsequent year’s yields.